Technologies

Trust our teams of specialists

The Murtfeldt Group provides you with comprehensive advice and develops the perfect solution to suit your requirements consisting of materials, expertise and services offered by the relevant specialised companies.

Semi-finished product manufacturing

For almost all industrial applications Murdotec has the perfect plastic for you: food-safe, for technical applications with perfect slide properties, highly wear-resistant and maintenance-free or extremely resistant, for particularly challenging applications. Use our Plastics Guide or get individual advice from our experts.

ADVANTAGES

- The right material for almost every application

- Can be modified on request

- Large standard range

- High level of availability from stock

- All intermediate dimensions

PRODUCTS

- Rods Sheets

- Pre-cut parts

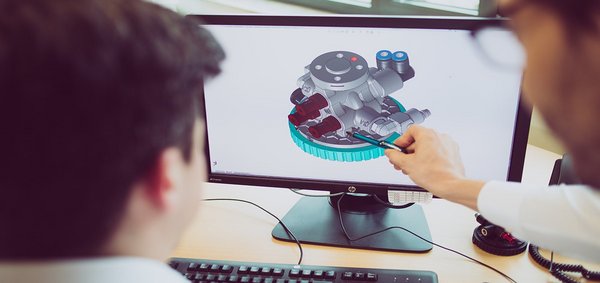

Machining

Since your machines and plants are unique, they need individual solutions. Produced precisely to suit your specifications Murtfeldt Kunststoffe The components you need. Even the smallest batch sizes can be accommodated. Murtfeldt Kunststoffe accommodates such requests by carrying out its production operations on state-of-the-art CNC milling machines. Our application engineers will offer you support with selecting the ideal material and with preparing design drawings.

ADVANTAGES

- Manufacturing of individual components

- We select the material and develop the design on request

- Wide range of technical and high-performance plastics

- Production according to your drawings or samples

- From a batch size of one

SAMPLE PRODUCTS

- Product turners

- Format sets

- Conveying screws

- Guides and slide profiles

- Individual components according to customers’ drawings

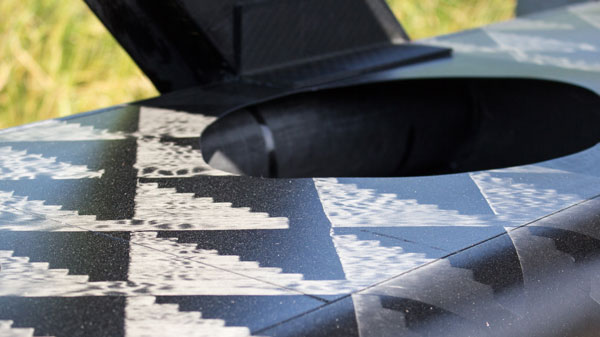

SLS (selective laser sintering) printing

When it comes to 3D printing, Murtfeldt Additive Solutions is in demand. In selective laser sintering (SLS), a high-power laser fuses plastic powders one layer at a time to form a component. Advantage: Here, the design freedom for plastic parts (which can also be excellently finished) is almost unlimited.

ADVANTAGES

- Component design according to customer requirements

- We develop the design on request

- Various finishing and refinement techniques

- From a batch size of one

SAMPLE PRODUCTS

- Individual components

- Loadable prototypes

- Replacement parts

- Small series

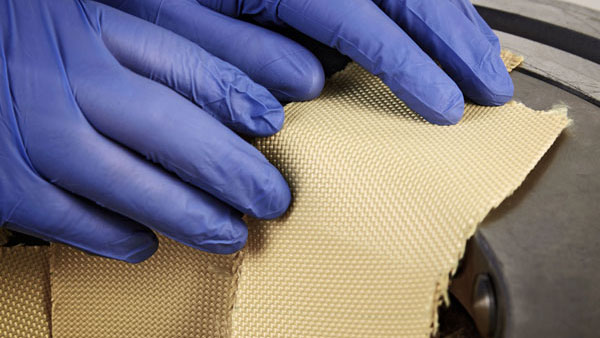

Fibre-reinforced composites

The subsidiaries carbovation and Crosslink are specialists in producing high-quality components made of fibre-reinforced composites. Whether solutions are for the automotive industry, aviation and aerospace, medical engineering, other industrial applications or sports equipment, wherever stability and lightweight construction have to go hand in hand our specialists from Lake Constance come into their own as one of the most established companies in this field in Germany.

ADVANTAGES

- Reduction of moving masses

- Use of smaller drive motors

- Energy conservation due to the lighter weight

- High weight-specific strength and rigidity

PRODUCTS

- Weight-optimised components

- Composite applications in medical engineering

- Radiolucent components

- Components with high dynamics

- High-strength structural components

Would you like more information?

We’ll be happy to help you if you have any questions about our technologies and solutions.

Contact form

How can we help you?

You can use the contact form provided to:

• Send us comments

• Ask us questions

• Request a quote

• Voice criticism

To submit your request, you must complete the mandatory fields marked with an asterisk (*). All other information is optional.

We will only use the information you provide to respond to your request. We will store the data you enter and forward it internally to the relevant employees for this purpose. We do not disclose your data to third parties as a matter of principle.

You will find more information about data protection in our company in our privacy policy.